I spent months calling factories, only to hear the same answer: "Sorry, our MOQ is 3,000 pieces." My small business couldn’t risk that investment.

The real MOQ for custom LCD writing tablets ranges from 10 to 3,000 pieces, depending on customization level, with most factories requiring 3,000+ units while select manufacturers like us accept orders as low as 10 pieces for basic customization.

Let me reveal why factories set these limits and how you can find suppliers who understand your needs.

What Can You Actually Customize on an LCD Writing Tablet?

I thought customization meant just adding a logo. Then I discovered the full range of possibilities that transformed my product line.

You can customize shell colors, stylus design, button styles, packaging, logos, instruction manuals, stickers, patterns, and even create entirely new shapes through custom molding, with each element affecting MOQ requirements differently.

!

Complete Customization Options Breakdown

Working with manufacturers taught me the hierarchy of customization. Basic modifications like changing shell colors or adding logos require minimal setup. I can get these done with orders of 10-500 pieces. Mid-level changes include custom button designs, unique stylus shapes, or specialized packaging. These typically need 1,000-2,000 unit commitments.

| Customization Type | MOQ Range | Setup Cost | Lead Time |

|---|---|---|---|

| Logo Printing | 10-500 | $50-100 | 7-10 days |

| Shell Colors | 500-1,000 | $200-300 | 10-15 days |

| Custom Packaging | 1,000-2,000 | $300-500 | 15-20 days |

| Shape/Mold | 3,000-5,000 | $1,000-3,000 | 30-45 days |

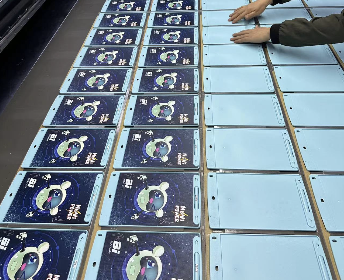

Advanced customization opens exciting possibilities. Custom shape molding lets you create unique cartoon characters or branded designs. I’ve seen tablets shaped like dinosaurs, unicorns, and robots. These require higher MOQs but create products nobody else can copy. The investment in custom molds pays off through exclusive market positioning.

Can You Add Your Logo to LCD Writing Tablets?

I worried logo customization would be complicated and expensive. The reality surprised me with its simplicity and affordability.

Adding your logo to LCD writing tablets is the easiest customization option, achievable through silk screening, pad printing, UV printing, or heat transfer, with MOQs starting at just 10 pieces and costs around $0.10-0.30 per unit.

Logo Application Methods and Requirements

Each printing method serves different needs. Silk screening works best for simple, bold logos with few colors. I use this for most orders because it’s durable and cost-effective. Pad printing handles curved surfaces and multi-color designs well. UV printing creates photo-quality results perfect for detailed logos. Heat transfer offers full-color options but costs more per unit.

Logo placement affects both aesthetics and cost. The front shell offers maximum visibility but some clients prefer subtle back placement. Multiple logo positions increase brand presence but add printing steps. I learned to provide high-resolution files in vector format to ensure crisp results. Most manufacturers need AI, EPS, or PDF files for best quality. Color matching requires Pantone references, though some flexibility exists with standard colors.

How Long Does It Really Take to Manufacture Custom LCD Writing Tablets?

I once promised customers delivery in two weeks, not knowing the real timeline. That mistake taught me valuable lessons about production schedules.

Manufacturing custom LCD writing tablets takes 10-15 days for basic customization, 20-30 days for complex modifications, plus 7-10 days for shipping, with the complete process from design approval to delivery typically requiring 25-40 days total.

Complete Production Timeline Breakdown

The process starts with design confirmation. I send my requirements and receive mockups within 2-3 days. Approval triggers sample production, taking 3-5 days for physical prototypes. Once I approve samples, mass production begins. Simple logo printing needs 10-15 days while custom colors or packaging extend this to 20-25 days.

| Production Stage | Standard Time | Rush Option | Notes |

|---|---|---|---|

| Design Mockup | 2-3 days | 1 day | Digital only |

| Sample Making | 3-5 days | 2-3 days | Physical sample |

| Mass Production | 10-15 days | 7-10 days | 10-2,000 units |

| Quality Check | 1-2 days | Same day | Final inspection |

| Shipping | 7-10 days | 5-7 days | Air freight available |

Shipping adds another layer of timing considerations. Sea freight saves money but takes 25-35 days. Air freight costs more but delivers in 5-7 days. I balance urgency against budget, often using air freight for samples and sea freight for bulk orders. Building buffer time into customer promises prevents disappointments.

Why Do Most Factories Refuse Small Custom LCD Tablet Orders?

I couldn’t understand why factories turned away business. Then I learned the economics behind their decisions.

Most factories refuse small custom LCD tablet orders because setup costs, production line adjustments, material waste, and opportunity costs make orders under 5,000 pieces unprofitable, forcing them to focus on large-volume clients.

Four Real Reasons Factories Reject Small Orders

First, setup costs remain fixed regardless of order size. Changing molds, adjusting machines, and preparing materials costs the same for 10 or 5,000 pieces. Second, production efficiency drops dramatically with small batches. Workers need time to perfect each process, but small orders end before reaching optimal speed. Third, material suppliers impose their own minimums. Ordering custom-color plastics or special LCD screens often requires quantities that exceed small orders. Fourth, opportunity cost hurts most. While producing your 10 pieces, factories miss chances for 50,000-piece orders from bigger clients.

How We Solve This Industry Pain Point

We structured our operations differently to serve small-batch customers. Dedicated small-order production lines run continuously, eliminating repeated setup costs. We maintain inventory of common materials, avoiding supplier minimums. Our pricing model accounts for smaller margins but higher order frequency. Most importantly, we see small orders as relationship builders. Today’s 10-piece buyer often becomes tomorrow’s 5,000-piece customer. This long-term view drives our willingness to accept orders others refuse.

Tips for Finding the Right Supplier

Finding suppliers who accept small orders requires strategic searching. Look beyond the biggest factories to mid-sized operations with flexibility. Trade shows reveal suppliers’ real attitudes better than websites. Ask directly about small-batch capabilities early in conversations. Check if they have experience with your market’s requirements. Request references from other small-batch customers. Evaluate their communication responsiveness as an indicator of service quality. Consider working with trading companies that aggregate orders to meet factory minimums. Most importantly, build relationships before needing rush orders.

Conclusion

Understanding real MOQs for custom LCD tablets helps you navigate supplier relationships, plan inventory investments, and find partners who support your business growth regardless of order size.

You may also be interested in:

Contact Us

Phone

+86 18975761579Website

ruiyiboard.comAddress

Shenzhen Longhua, Guangdong, China

Shenzhen Ruiyi Plastic Products Co., Ltd. is a professional manufacturer focused on eco-friendly writing products since 2016.

Our mission is to provide paper-free, ink-free, safe and environmentally friendly electronic writing solutions.