Custom Branding Options for Kids LCD Writing Tablets: From Logo to Packaging?

Custom branding transforms generic LCD writing tablets into powerful marketing tools and premium products. Many businesses miss opportunities to create memorable brand experiences through thoughtful customization strategies.

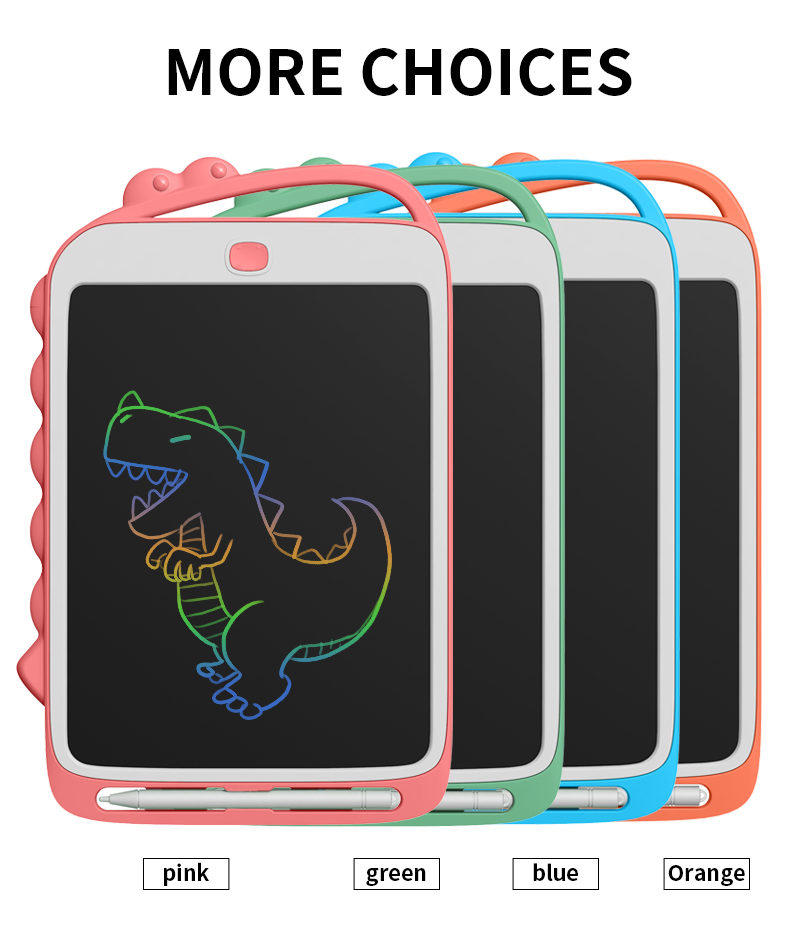

Customize housing colors, logo placement, packaging design, and accessory branding for kids’ LCD writing tablets. Professional branding increases perceived value by 40-60% while building brand recognition and customer loyalty.

I learned the power of custom branding when comparing two identical products at a trade show. The generic tablet sold for $8, while our custom-branded version with company logo and themed packaging commanded $14. This experience showed me how branding creates value beyond product functionality.

Corporate Gift Guide: Customizing LCD Writing Tablets with Your Company Logo?

Corporate gifts require professional appearance and brand consistency to make lasting impressions on clients and employees. Poor branding execution can damage professional relationships instead of strengthening them.

Focus on subtle logo placement, professional color schemes, and premium packaging for corporate LCD writing tablet gifts. Laser engraving and UV printing provide durable, professional branding that reflects company quality standards.

!

My biggest corporate gift success came from creating custom LCD writing tablets for a tech company’s client appreciation program. We laser-engraved their logo on premium black housings and created custom gift boxes with their brand colors. The client reordered three times that year because recipients kept asking about the tablets.

Logo placement strategy affects both aesthetics and functionality for corporate gifts. Front-center positioning provides maximum visibility but can interfere with writing area, while back-panel placement maintains clean writing surface while ensuring brand presence. Corner placement offers balanced visibility without functional compromise.

Professional color coordination should align with corporate brand guidelines while maintaining product appeal. Conservative colors like black, navy, or gray suit most business environments, while accent colors can incorporate specific brand elements. Our factory maintains extensive color libraries matching major corporate brand standards.

Packaging customization creates premium unboxing experiences that reflect corporate professionalism. Custom boxes with foam inserts, branded tissue paper, and instructional cards enhance perceived value while reinforcing brand messaging. These elements transform simple gifts into memorable brand experiences.

Personalization options include individual employee names, department logos, or custom messages for special occasions. Laser engraving allows precise text customization while maintaining professional appearance. These personal touches increase gift appreciation and usage rates among recipients.

Corporate Branding Elements

| Branding Option | Durability | Professional Appeal | Minimum Order | Lead Time |

|---|---|---|---|---|

| Laser Engraving | Permanent | Highest | 100 units | 1-2 weeks |

| UV Printing | High | High | 300 units | 2-3 weeks |

| Screen Printing | Medium | Medium | 500 units | 2-3 weeks |

| Heat Transfer | Medium | Medium | 200 units | 1-2 weeks |

| Custom Packaging | High | Highest | 500 sets | 3-4 weeks |

Quality standards for corporate gifts must exceed consumer product expectations because business relationships depend on positive impressions. Every detail from logo clarity to packaging presentation reflects company standards and attention to quality.

Bulk ordering considerations include storage requirements, distribution logistics, and timing coordination with corporate events or holidays. Planning ahead ensures proper customization time while securing better pricing through volume commitments.

Documentation requirements include brand guideline compliance, logo usage rights, and quality approval processes. Professional corporations often require detailed specifications and approval workflows before authorizing custom branding projects.

Eco-Friendly Customization Options for Children’s LCD Writing Tablets?

Eco-friendly customization appeals to environmentally conscious parents while supporting sustainable business practices. Traditional customization methods often involve harmful chemicals or non-recyclable materials that contradict environmental messaging.

Choose water-based inks, recyclable packaging materials, and sustainable branding methods for eco-friendly LCD writing tablet customization. These options maintain quality while supporting environmental responsibility and appealing to green-conscious consumers.

Environmental consciousness became crucial when a major retailer rejected our proposal due to non-sustainable packaging. We redesigned our entire customization approach using recyclable materials and eco-friendly inks, which not only secured the contract but opened doors to other environmentally focused customers.

Sustainable materials selection includes recyclable plastics, biodegradable packaging, and eco-friendly inks that minimize environmental impact. Our factory uses water-based printing inks that eliminate volatile organic compounds while maintaining vibrant colors and durability.

Packaging sustainability involves using recycled cardboard, soy-based inks, and minimal plastic components in custom packaging designs. These materials maintain protective qualities while reducing environmental footprint and appealing to eco-conscious consumers.

Energy-efficient manufacturing processes reduce carbon footprint during customization production. Our facility uses solar power for certain operations and implements energy-saving technologies that lower environmental impact without compromising quality standards.

Recyclability considerations ensure customized products and packaging can be properly disposed of at end-of-life. Clear recycling instructions and material identification help consumers make responsible disposal choices while supporting circular economy principles.

Environmental messaging integration allows brands to communicate sustainability commitments through product customization. Eco-friendly logos, sustainability certifications, and environmental messaging reinforce brand values while educating consumers about responsible choices.

Sustainable Customization Materials

- Water-based printing inks without VOCs

- Recycled cardboard packaging with soy-based inks

- Biodegradable foam inserts and protective materials

- Recyclable plastic housings with clear identification

- FSC-certified paper materials for documentation

- Solar-powered manufacturing processes where possible

- Minimal packaging design reducing material waste

Certification compliance includes environmental standards like FSC certification for paper products and GREENGUARD certification for low-emission materials. These certifications provide third-party verification of environmental claims while building consumer trust.

Cost considerations for eco-friendly customization typically add 10-15% to standard options but create significant value through environmental positioning and consumer appeal. Many customers willingly pay premiums for demonstrated environmental responsibility.

Market positioning advantages include differentiation from competitors, appeal to environmentally conscious consumers, and alignment with corporate sustainability initiatives. These benefits often justify higher costs through premium pricing and customer loyalty.Complete Guide to Customizing LCD Writing Tablets for Children’s Markets?

Children’s market customization requires understanding child preferences, parent concerns, and safety regulations while creating appealing products. Generic approaches fail because children respond to specific visual elements and interactive features.

Prioritize cartoon characters, bright colors, educational themes, and child-safe materials for children’s LCD writing tablet customization. Combine visual appeal with educational value to satisfy both children’s desires and parents’ educational goals.

My children’s product breakthrough came from observing kids at a toy store. They ignored elegant designs but gravitated toward tablets with cartoon characters and bright colors. This insight led me to develop themed customization options that tripled sales in children’s markets.

Character licensing opens opportunities for popular cartoon characters, movie themes, and educational brands that children recognize and desire. Licensed characters command premium pricing while ensuring strong market appeal, though licensing fees and approval processes require careful planning.

Color psychology influences children’s product preferences with bright, contrasting colors performing better than subtle tones. Primary colors, rainbow themes, and color-changing elements capture attention while supporting creative expression and learning activities.

Educational theme integration combines entertainment with learning objectives that appeal to parents and teachers. Alphabet themes, number games, drawing tutorials, and STEM concepts transform entertainment products into educational tools that justify higher prices.

Size considerations for children include appropriate tablet dimensions, button placement, and grip ergonomics. Smaller hands require different proportions than adult products, while anti-drop features become essential for active children who may drop or throw tablets.

Safety customization includes rounded corners, break-resistant materials, and child-safe components that prevent injury risks. Our anti-drop screw structure prevents small parts from creating choking hazards while maintaining product functionality and durability.Children’s Customization Elements

- Licensed cartoon characters and popular themes

- Bright, contrasting color combinations

- Educational content integration and learning themes

- Child-appropriate sizing and ergonomic design

- Safety features including anti-drop screw structures

- Interactive elements and engaging visual designs

- Durable materials resistant to rough handling

Interactive features like textured surfaces, sound effects, or light elements enhance engagement while maintaining educational value. These features increase product appeal but require careful design to avoid overwhelming core functionality.

Durability requirements for children’s products exceed adult standards because children test products through rough handling, dropping, and creative misuse. Reinforced construction, impact-resistant materials, and robust electronic components ensure products survive active use.

Parent appeal factors include educational value, safety features, and developmental benefits that justify purchase decisions. Products that clearly communicate learning benefits while maintaining child appeal achieve strongest market success.Quality Control in Custom LCD Writing Tablet Manufacturing for Kids?

Quality control becomes critical when customization involves children’s products because safety standards are stricter and tolerance for defects is zero. Poor quality control can result in safety hazards, regulatory violations, and permanent brand damage.

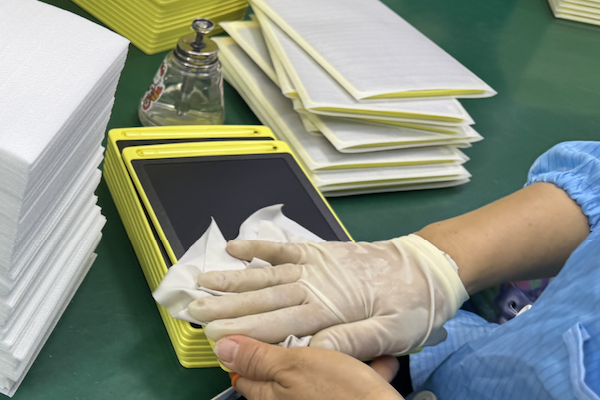

Implement specialized inspection protocols for custom branding elements, child safety verification, and durability testing for children’s LCD writing tablets. Focus on logo adhesion, material safety, and anti-drop screw integrity throughout production.

Quality control saved my business when we discovered logo adhesion problems during final inspection. The printing wasn’t bonding properly to certain plastic formulations, which would have led to peeling logos and customer complaints. Catching this issue prevented a major quality crisis and customer relationship damage.

Custom branding inspection includes logo clarity, color accuracy, placement precision, and adhesion durability for all branding elements. Each customization method requires specific inspection criteria with pass/fail standards based on visual quality and durability requirements.

Material safety verification ensures all custom elements meet children’s product safety standards including lead content, phthalate restrictions, and chemical migration limits. Custom inks, adhesives, and decorative elements undergo testing to verify compliance with applicable regulations.

Durability testing simulates real-world usage including scratching, washing, temperature extremes, and UV exposure to verify custom branding maintains appearance and integrity throughout product lifetime. These tests prevent field failures and warranty claims.

Batch consistency monitoring ensures custom colors, logo placement, and quality standards remain consistent across production runs. Color matching equipment and standardized inspection procedures maintain quality consistency even with different production operators.

Child safety integration includes anti-drop screw verification, sharp edge detection, and small parts testing specifically focused on custom elements that might create safety hazards. Custom decorative elements require particular attention to prevent detachment risks.Quality Control Checkpoints

- Custom logo clarity and placement accuracy verification

- Branding adhesion and durability stress testing

- Material safety compliance for all custom elements

- Color consistency across production batches

- Child safety feature integrity verification

- Packaging quality and presentation standards

- Pre-shipment final inspection and documentation

Documentation requirements include detailed inspection records, test results, and compliance certifications for all custom elements. This documentation supports regulatory compliance while providing traceability for any quality issues.

Supplier management ensures consistent quality from all customization vendors including printers, packaging suppliers, and decorative element providers. Regular audits and quality agreements maintain standards across the entire supply chain.

Continuous improvement processes track quality metrics over time to identify trends and prevent recurring issues. Statistical analysis helps optimize processes while maintaining high quality standards for custom products.Conclusion

Strategic customization transforms standard LCD writing tablets into powerful brand tools and premium products through professional branding, eco-friendly options, child-focused design, and rigorous quality control.

You may also be interested in:

Contact Us

Phone

+86 18975761579Website

ruiyiboard.comAddress

Shenzhen Longhua, Guangdong, China

Shenzhen Ruiyi Plastic Products Co., Ltd. is a professional manufacturer focused on eco-friendly writing products since 2016.

Our mission is to provide paper-free, ink-free, safe and environmentally friendly electronic writing solutions.